CYLINDER

MOLD MULTIHULL CONSTRUCTION

Cylinder

Molded multihulls have come a long way in the last twenty six years. By now in 2009 there are hundreds of CM built

multis out there building or sailing now. The original KAMANU, the first C.M. USCG certified charter catamaran

has been sailing nonstop for nearly twenty five years. Dozens of C.M. cats are now USCG certified

to carry passengers. Builders on all

continents are finding out that Cylinder Molding can give them the very highest

quality wood/epoxy multi hulls in less time than any other one-off construction

system there is. With the economy

in shambles, the fact that a CM hull cost about 50% less to build than a foam/glass/epoxy

one probably explains the recent surge in interest in CM multihulls.

And, unlike other molding systems, CM lets builders

get the hull shapes they need, not the ones the system allows. Here is how it evolved.

Many

of my friends and clients share a curious dilemma with me; we crave sleek, high

speed multihulls, but we cannot possibly afford them. Over the years we have

developed a dodge to get into these fantastic boats at a lower cost and in much

less time than usual. The dodge is a rapid hull construction system, usually called

cylinder mold, though nothing about it resembles a cylinder. The hull sections

that we use are conic sections like ellipses and parabolas, but not

cylinders. I have been more accurately

calling it vacuum-formed plywood, but the name “cylinder mold” seems to have

stuck, so it will be used.

Cylinder

molding is an odd way to build boats. It is a process where vacuum pressure and

epoxy are used to form thin sheets of plywood into thicker panels that are used

to build hulls. Instead of the project

progressing slowly in an incremental, linear, cumulative fashion, you start

with the skin and work inward. Instead of being able to take continual stock of

your progress, you will metamorphose raw materials into a hull in three major

steps. Each major step will last only long enough for the epoxy to cure. Then,

except for detailing and trimming, like it or not, it is done. So curmudgeons

beware! Not everyone is suited to build this way. Instead of carefully

following directions in a repetitive haze, a builder needs to make rapid eyeball

judgements, with confident calls. To

help builders make those eyeball judgements, we offer a Construction Manual on

Video or DVD. It is available to

builders of CM multihulls.

“If

you want curved plywood-curve plywood!”

Stig

Hoffstedt

Sweden

THE

NEED

I

feel that multihull builders need a system of generating hulls, uncompromising

hulls at very low cost and with far less work than usual. A fast building system that creates slow

hulls is of no use. They would have to

be of the most efficient round bilge shapes.

Also,

I have always been curious about why many multihull designers force builders to

work outside the nature of materials.

Manipulating a blob of fiberglass resin into a smooth, fair, thin shape

can only be done by applying many many hours.

Cold molded plywood or Constant Camber TM construction

systems take thin, smooth, fair sheets of plywood and chop it into bits. Then they apply many many hours to convert

it back to plywood again. Rough plywood.

It makes no sense.

I

strongly believe in using the high quality industrial materials all around

us. To take fullest advantage of the

quality, one has to stay in the nature of materials. For example, most CM hulls are made from 3mm Asian plywoods. These thin plywoods are fantastically smooth

and fair. Hulls made from them are

smooth and fair. Builders need a

construction system that lets them take advantage of the industrial processes

already out there. CM does let builders

work in the nature of the plywood. The

results are lower cost, fewer hours required, and better quality.

The

technology of modern multihulls is changing very rapidly. A design that was

called “state of the art” two or three years ago, is obsolete and overweight

now. The implications are several. If

you survey the common methods of hull construction, there are a lot of

expensive wrong turns available to one, both in dollars and in product. Lets look at some of them.

Buying

a very sophisticated multihull design, such as a one-off composite craft,

will cost a great deal of money. Also, composite one-off multihulls are

extremely time consuming to build. By the time an amateur builder finished, the

design that was the latest state-of-the-art when he began might be obsolete.

Still,

buying a less expensive boat, such as a production run composite boat,

gets a product that is by definition obsolete.

The accountants will still want to get as many boats as possible off of

those ten year old molds.

Kit

Panel KSS tm

by Kelsall seem to be rapid to build. In

fact, in one of the recent issues of a magazine, it looked like he had just

discovered cylinder molding, but with fiberglass. In the pictures below, one is a recent KSS hull and the other is

a CM hull from 15 years ago. Both

are developed and both look to be wired along the keel. Sweet. The Cm hull is the

one on the right. It does look a little

straighter along the keel to me.

At a recent Multihull design conference, in Miami, I watched several people working late into the night to build

a little KSS hull. By the middle of the second day they basically

had a pair of panels done. That accomplishment

would be about 5 hours into a CM hull. I do notice that they never count the time

to build a bagging table in the time-to-build.

In CM, the panel is its own bagging table, as it were. One is not needed.

At a recent Multihull design conference, in Miami, I watched several people working late into the night to build

a little KSS hull. By the middle of the second day they basically

had a pair of panels done. That accomplishment

would be about 5 hours into a CM hull. I do notice that they never count the time

to build a bagging table in the time-to-build.

In CM, the panel is its own bagging table, as it were. One is not needed.

Next

I saw the chop saw come out and the hull panels got chopped along the keel

into short darts. These bits were

then bent into a profile and glassed over.

The primary structure was secondary bonded.

Their basic premises, chopping the full hull length fibers, and depending

on secondary bonding for primary strength, are contrary to modern composites

practice. (see Professional Boatbuilder #66, page 78) The best study shows

that a polyester secondary bond with a 12/1 taper ratio has about 20% the

strength of the same thickness of original lamiminate. See tensile PDF. In

Miami I saw no taper, so the strength must have been even less than 20%. The

full length, properly oriented fibers, used with epoxy,(see

epoxy) that are so important to multihull rigidity and strength are ignored

as I understand KSS. The level of

smoothness and fairness that I saw in Miami, especially below the waterline,

would be utterly unacceptable in a modern boatyard. KSS is actually a variation on platen molding, which has been used

to build mega-yachts for decades. KSS

has been changing constantly, while declaring each version of itself to have

“no downsides”. It is pleasing to

see composite panels apparently being developed similar to CM. I believe there are more elegant ways to do

that. So, I did publish and present

a paper on rapid composite construction in 1992.

See the paper, and other articles.

A

custom cold-molded boat may be seen as a compromise between the

two above choices. It may be more modern than the factory run boat, and less

expensive than a composite one-off boat. However that compromise ignores one of

the major reasons that multihulls are better now than they were three years

ago, that is fiber orientation. The modern boats have the strongest fibers

oriented with the lines of stress. The older designs are what is called

quasi-isotropic, meaning for practical purposes, equally strong in all

directions. But hull stresses do not run equally in all directions, so that

would be an inefficient way to build. A triple diagonal hull would be

considered quasi-isotropic. A double diagonal hull would be even less

structurally efficient. It would have only a third the bending strength in the

plane of plies, compared to a properly oriented plywood skin of equal

thickness. For me, a cold-molded hull is too clumsy in its structural

attributes alone, ignoring for now the large amount of work required to build

it.

Strip plank might

be a good choice. Where complex hull shapes

are called for I specify these. It is

again however more time consuming. A

strongback must be set up, the station patterns lofted, beveled and lined up. Then the stripping material has to be

beveled and scarphed to full length.

Each of these pieces has to be individually epoxied on the joining

faces. Then every piece has to be

carefully fastened to the mold with structural bog spread between every

piece. The excess bog is squeeged away

and the whole thing is faired. Finally

roving reinforcement is laid up on both side of the hull, and it is surfaced

with bog and faired.

Note

however that the strip pieces can’t just be laid down. Since the hull gets skinnier at the ends,

some strips have to be cut back at the ends.

To resist those multihull global loads, the sheer and keel areas must be

full length. That means that many of

the pieces between have to be carefully fitted in. It is a fussy, time consuming job requiring lots of bog. For complicated or fat wood/epoxy hulls I

usually call for strip plank foam.

Fusion Hulls

can be a combination of CM and core materials.

They can be a CM bilge with composite topsides or a full on CM hull with

core bagged inside to eliminate stringers.

Another

choice might be sheet plywood hulls. Face grain oriented plywood

could develop more structural performance than cold molded hulls but the

choices are limited. They would have to be a “V” section, a chine hull, or a

developed compound shape. A”V” section is absolutely out of the question. There

may not be any other way to come up with less boat using more material. A

chined hull has poor hydrodynamics, and enough structural discontinuities to be

an unacceptable choice for an optimum hull.

Also,

aside from the structure, even the simplest chine hull, even a “V” section will

be noticeably more work than the same size cylinder molded hull.

The

developed hull or Stressform tm, compounded from sheet

plywood, has the most promise; but there are difficulties here too. Boats

bigger than daysailers need hulls of a certain minimum thickness. Thick

plywood, however, is very difficult to compound. Imagine springing a full, high

prismatic shape into a sheet of 12mm marine plywood. It won’t go. So the choices are to keep the skin thin, and

consequently, the boat small, or work something else out. Cylinder Mold

Technology is the something else. And it works out very well.

HISTORY

Cylinder

molding is a relatively recent invention. It requires the simultaneous

combination of several rather modern technologies:the use of plywood, of modern

epoxy, and of vacuum bagging.

The

earliest record that I find of this sort of boat construction seems to be by

Uffa Fox with his tortured plywood hulls. While he did not use epoxy or vacuum

bagging, our molding technology owes a good deal to his developed or tortured

ply boats. (The Gougeon brothers book on boat construction has a very complete

chapter on the construction of developed plywood boats.) Certainly cylinder

mold hull building was around before I began using it. The problem was, the panels

that I saw being built didn’t look like anything that I would want on my boat.

They were made with rough, nasty veneers, and the section curve was the same

for the topsides as it was for the bilge. I knew boats shouldn’t look like

that.

In

1980, when I got a high quote to build two new 30' amas for my tri, I decided

that I had to find a way to get a pair of amas for a lot less money. They had

to be good looking amas, and had to be built quickly.

I

managed it, using cylinder mold technology. Now, between myself and other

builders, at least 400 hulls later (maybe as many as 500) it can be called a

very successful system. Here is what cylinder molding can do.

POTENTIAL

In

a reasonably equipped woodshop, you can expect to build a cylinder mold in six

or eight hours. To build a 35' hull for example, you can expect to build a full

length mold for seventy or eighty dollars.

The mold for a full standing headroom hull will be just over a hundred

dollars. On that mold you will be able

to lay up a full length hull panel in two or three hours. Preparing for the

layup will take up to a half day, depending on the size of boat. The panel for this 35' hull will be made

from a dozen or so sheets of thin (usually 3mm) plywood. These sheets will be

coated with epoxy, laid on the mold two or three thick, and vacuum-bagged

together into a panel. The panel will become one continuous sheet of plywood,

four or more feet wide and thirty five long, with the transverse curve already

in it.

When

the panels are compounded into hulls, they will have several important

characteristics. The face grains will be oriented along the lines of greatest

bending stress; the surface will be smooth already, and because the process of

developing a hull treats it like a three dimensional batten spline, it will be

automatically fair.

You

can expect a two layer (6mm.) hull skin with the outside glassed, to weigh

.9 to .95 lbs. per square foot. That is very close to a comparable cold-molded

or composite hull weight using E glass. The hull costs will range from $3.00

per square foot for Asian plywood to $4 or more per square foot for Bruynzeel

plywood. Cold-molded hulls will be in a similar cost range, but composite

one could be double the price. A composite hull using high modulus exotic

fabrics could run ten times that price per square foot.

A

moderately experienced builder can expect to deliver a simple hull, an ama for

instance, decked and glassed, at the rate of 12 to 15 minutes per square foot

of hull. For comparison, a cold-molded oneoff hull will run between 2 and 3

hours per square foot, without decks.

Paint ready requires the usual smoothing time, but the developed plywood

surfaces are already several orders smoother than cold molded or composite

surfaces. Fairing and filling will be needed at the keel area, but the large,

flatter surfaces usually only need smoothing.

Using

this evolution from Uffa Fox’s fold up boats, one can build hulls, even large

hulls, at labor and cost savings that are unattainable by other systems. At the

same time the structural integrity is much better.

CONSTANT

CAMBER

I

am still asked if this is like Constant Cambertm.

Except

for the fact that we both use wood, epoxy and vacuum bagging, the answer is no.

There is no similarity. Building the

Constant Camberä mold alone looks to me like a major

operation. My sense is that the hulls

made that way have more in common with cold- molded hulls. Just count the number of pieces, and what

has to be done to them. In fact, over

the last few years CC has been adopting many of the techniques that we started

with, including full length molds, elliptical mold sections, and on one boat,

full sheets of plywood. They still have

not been using scarphs and proper fiber orientation.

Also,

I have yet to see a CC hull that has a good modern hull shape to my eyes. I’m not seeing the minimum wetted surface

round sections that I like, and the nice wide transoms that dampen pitching and

give powerful reaches.

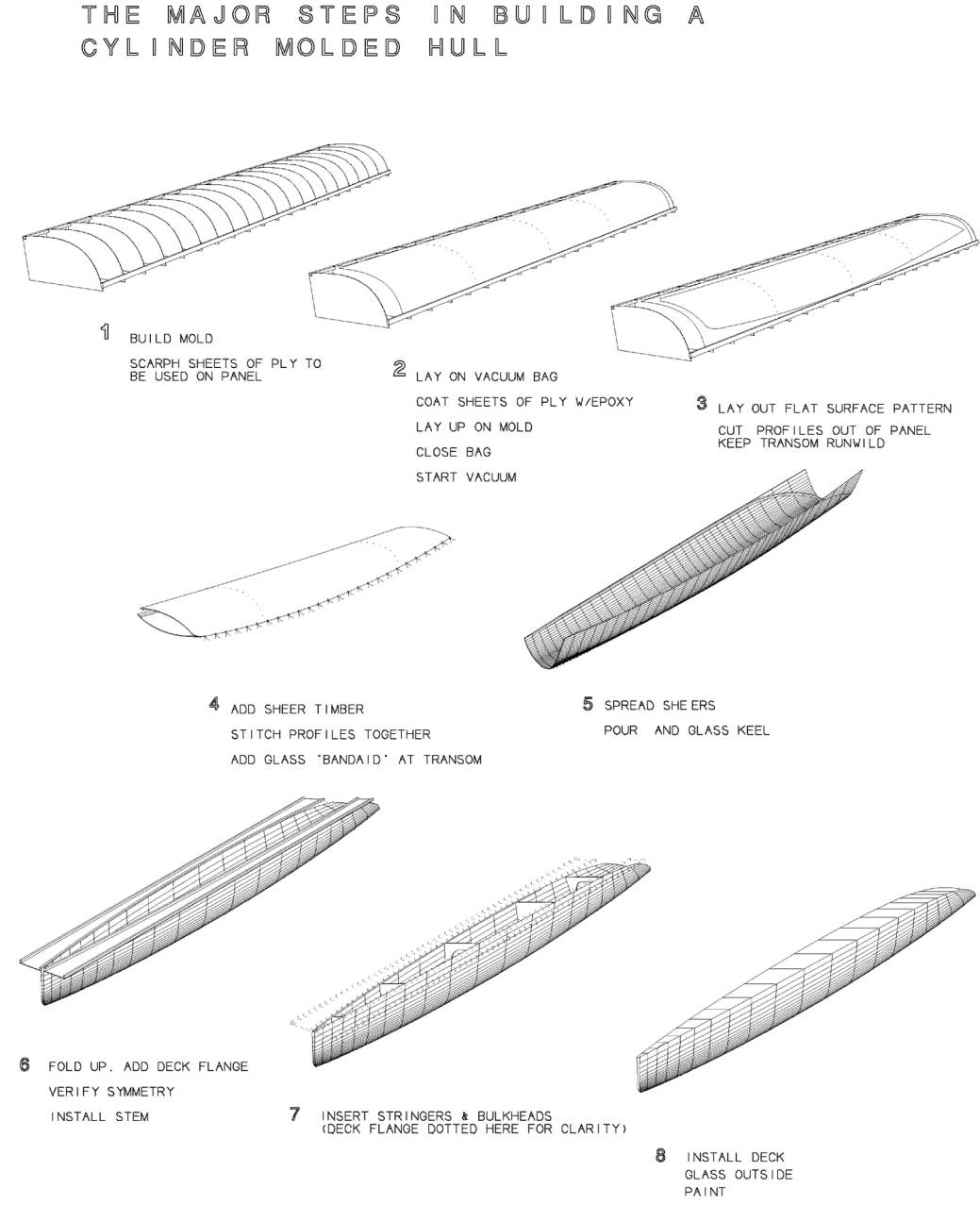

CONSTRUCTION

Lets

take a run through the stages of hull construction. We can build that 35' ama

as an example.

I

will not include the very significant time required to set up your shop, or the

time required to collect materials. There are too many possible differences

between builders and situations.

Building

the mold will be done first. To do that, cut out enough identical mold sections

to allow one for every two feet of panel length. Locating the sections at

exactly two feet is not necessary, but making the sections identical is. Once

they are cut out, from plywood (CDX or worse), stack them together and compare

them. If they are at all

different from each other, a grinder will make them all match.

A lumber cleat is added top and bottom to finish the mold. The first major step is to build panels. Each

hull will have two full length panels, port and starboard. A scarphed edge

must first be put on every thin sheet of plywood to be used on the entire

hull. That is easy. Stack the sheets

in an even 8 to 1 step back, using a grinder to give them identical scarphs.

It will take about an hour. Consider that every piece in a panel will be both

lapped and scarphed to the others near it.

different from each other, a grinder will make them all match.

A lumber cleat is added top and bottom to finish the mold. The first major step is to build panels. Each

hull will have two full length panels, port and starboard. A scarphed edge

must first be put on every thin sheet of plywood to be used on the entire

hull. That is easy. Stack the sheets

in an even 8 to 1 step back, using a grinder to give them identical scarphs.

It will take about an hour. Consider that every piece in a panel will be both

lapped and scarphed to the others near it.

A

vacuum system must be set up to bag a panel. I usually use a shop vac. It can

both clean your shop and suck a vacuum to make panels. For the bagging material

we use 4 or 6 mil polyethylene. For the bag edge seal, storm window snap bead

has proven to cause the lowest grief at best cost. It can be used a dozen

times, is clean, rapid, and not bothered by wrinkles and dust. As a diffusion layer inside the bag,

bubble-pak is best.

I have laid up panels by myself, but it is many times faster

to have a helper or two. Enough sheets of 3mm plywood to build a panel will

be coated with epoxy on the scarphs and mating faces only. When this is done,

the sheets of plywood are laid on the mold. Finally close the bag and start

the vacuum pump up. To build their last panel of the 36’KAMANU, Schooner Creek

Boatworks spent only 38 minutes. It takes me an hour or two working alone.

Remember again that every sheet of thin plywood forming a panel is both lapped

and scarphed to the others. The result is a panel that behaves, when

compounded, like the huge, fair, batten spline it is. Naturally that will

make a stronger hull. After the bag is checked for leaks, the vacuum pump

must run long enough for the epoxy to cure, usually eight or ten hours. If

you have not done vacuum bagging before, it is quite amazing. Your own mild

mannered shop vac will suck enough vacuum that you cannot physically lift

the bubble pak off of the panel.

I have laid up panels by myself, but it is many times faster

to have a helper or two. Enough sheets of 3mm plywood to build a panel will

be coated with epoxy on the scarphs and mating faces only. When this is done,

the sheets of plywood are laid on the mold. Finally close the bag and start

the vacuum pump up. To build their last panel of the 36’KAMANU, Schooner Creek

Boatworks spent only 38 minutes. It takes me an hour or two working alone.

Remember again that every sheet of thin plywood forming a panel is both lapped

and scarphed to the others. The result is a panel that behaves, when

compounded, like the huge, fair, batten spline it is. Naturally that will

make a stronger hull. After the bag is checked for leaks, the vacuum pump

must run long enough for the epoxy to cure, usually eight or ten hours. If

you have not done vacuum bagging before, it is quite amazing. Your own mild

mannered shop vac will suck enough vacuum that you cannot physically lift

the bubble pak off of the panel.

After completing the two panels (port & starboard) necessary

to build a hull, a pattern called the flat surface profile is laid out on

each panel. Cutting along the pattern lines gives two identical half hulls.

Identical sheer timbers are next glued to each profile.

After completing the two panels (port & starboard) necessary

to build a hull, a pattern called the flat surface profile is laid out on

each panel. Cutting along the pattern lines gives two identical half hulls.

Identical sheer timbers are next glued to each profile.

The

reflected profiles are wired together along the keel. The sheers are spread to

the distance noted on the plans. At the

bow area we install a composite stem.

The stem unit allows one to keep the stem area under control, a

condition that was a bit lacking in previous developed hull schemes.

The

next major step is the keel pour. The hull halves will now be fully joined. We

build the keel from a mixture of epoxy and fillers, under biaxial roving.

To

create the proper developed fullness, and to insure that port matches starboard,

a temporary deck flange is to be built. The final major step in hull building

is when the deck flange is set in place. The bulkheads and stringers may now

be added. Since the hull skin has already assumed a smooth fair surface, the

bulkheads must be fitted lightly. They should be a little under size to keep

from deforming the hull skin. With proper planning, the inside of the hull

may coated at the same time that the bulkheads are coved in and the stringers

are pushed in through the open transom. If the entire job is done in one “wet

out”, no inside sanding or bonding preparation is needed. I like that.

The

best decks seem to be built with composite cores bagged onto thin plywood.

There is time saving over using plywood stringers, and the cored decks reduce

the microfissuring that often occurs on the underside of epoxied plywood/stringer

decks.

After

the bilge wires are removed, and the edges trimmed, the keel has a layer of

biaxial tape added to the outside. Any necessary filling is done at the sheers

or keel, and the hull is sheathed with a layer of 4 oz. or 6 oz. glass cloth.

A

light, high performance hull can be built very quickly at low cost. This

technology should give one more of a chance to finish a boat before it becomes

outdated, or the money runs out.

This

is not to suggest that cylinder molding will make boats inexpensive. Hulls are only a small part of the cost of a

boat. Multis that are almost all hull

will see big savings. Bridgedeck cats

for example will see smaller relative time and cost savings from rapidly built

hulls.

PROBLEMS

Every

building system has limitations. CM is no exception. There are some

restrictions on the possible hull shapes. To keep building time down, CM hulls

should be simple curve sections.

Flares, steps, and hollows are not easily possible.

These

hulls must have slenderness ratios 10:1 or thinner at the waterline if they

have reasonable amount of rocker in the profile. Within these constraints

however, virtually any hull shape is possible.

Also,

as a designer, I cannot locate things in a cylinder molded hull with absolute

certainty. For instance, I could specify that a seat be located 14" below

the sheer level. I could not also state that it would be some exact distance up

from the keel. I can come close, but there is still some uncertainty. Two hulls

built from identical profiles but different plywood might come out slightly

different. You could not see the difference, but a tape measure might show it.

It is eyeball boat building, with ‘make port reflect starboard’ being the

dominant rule. If you must have exact accuracy in all aspects, this is not for

you. I’m happy to design boats for you

to be built in other construction systems.

We do many composite boats for clients where time and cost are less

important.

CM

hulls are better suited for some types of multis than others. I see CM as being ideal for hulls such as

tri amas or charter cats where interior living in the hull is not needed. I see CM as having the least advantage in

hulls such as livaboard cats where interior is everywhere in the hull and the

structure must be carefully finished.

Finally,

one must be careful about which plywood to use. Some types of excellent plywood

might be too stiff to compound. With

the great number of useful plywoods out there, that does not need to be a

problem.

THE

FUTURE

The

system is moving toward unprecedented dimensional certainty as I collect an

ever-increasing body of data from the boats that have been built. A mature CADD system makes that even easier.

In fact CADD (computer aided design and drafting) is a natural fit with CM. Changing the length, beam, or freeboard on a

building project is as easy as a rescale is on the computer. Adding eighteen more inches freeboard on a

40' tri main hull panel was done in about three minutes, by simply sliding the

flat surface pattern up 18". That

is about the same difficulty as a drawing rescale on the screen. Of course all KHSD multis are drawn using

CADD now, as they have been for 20 years.

Experiments

with strategies to allow fatter length/beam ratios on boats with larger amounts

of rocker have turned out very well. The result has been higher displacement

cylinder molded cruising boats than we ever thought possible years ago. At this

point as we keep exploring the envelope of possibilities, I must repeat, it

looks like virtually any slender, positive curve hull shape wanted is

possible.

A

mold system that we call the air mold is being developed. It consists of no mold at all, beyond the

lower channel. Hence the name.

Several

rapid composite hulls have been built using the various rapid construction

systems we have been developing. I will

get around to publishing them soon.

Design support takes so much time that publicity has to take back seat.

CONCLUSION

This

construction system, developed by people too poor to deserve boats, got us into

sleek, high speed multihulls that would be out of our reach otherwise. They are

also the highest quality boats we could have chosen. Cylinder Molded hulls may be the best possible choice for many

builders of multihulls.