Post-Apocalyptic Boatbuilding, or

How to Save the Money that You Need to Build a Boat During

a Time of Recession; Strategies and Substitutions to save Money on your Boat

Construction.

As the designer of some

several hundred boat building projects, I find myself lately often being asked

to advise on material substitutions and building strategy changes.† My work

is entirely multihulls, but this applies to any boats that benefit by being

careful about weight.†

Back in the 70ís when we

were building our early multihulls, they were basically hulls, beams and the

hardware we scrounged on and above the deck.† Compared to multis now, they

did not cost much.† We built them ourselves, probably we did not take out

a loan to build them and usually did not insure them.† If you built it yourself

and it crashed, you could fix it yourself.

In the go-go 90s through

maybe last year, that changed.† Newly wealthy sailors used the boats as a

matrix to attach cool toys to.† The value of the electronics and gadgets might

have exceeded even the value of the basic boat.† These boats were more often

than not owned by the bank and heavily insured.

For many sailors and sailors-to-be,

that might have changed with the recent economic excitement.† What can be

done now to get a boat?†

First,

turn off the news.† Next, put Gimmie Shelter

on the player.† Youíre still alive.† You need to get

away and go sailing.† Maybe you can get a boat without

the bank.

What is the boat like?

Sorting

out what the boat will be like and what it needs to

do is an important first step.† What do you really need?†

Does it need to have the giant flat screen television,

the air conditioner and the powerful electric generation

system?† Expensive cabinets and extensive systems can

vastly increase the cost of a boat. Downsizing the cost

does not always mean a boat that is too small to use

however, not to disparage small boats.† In multihulls,

longer waterline can be less expensive than a boatload

of gadgets.† That gives more safety, more payload and

better speed for less money than one might first think.

Building or Buying

While there are many bargains

for sale out there, they often have hidden surprises.† I maintain that you

can build a boat that you could not afford to buy, with better quality than

most of the ones you could buy.† For example, the boat you build will probably

be out of epoxy, unlike most of the boats for sale.† That provides much better

quality.

If you buy a boat, you

are paying a 10% commission.† Plans cost a lot less than that.

Also, according to the

tax agencies in my area, you labor is not worth a cent in boat value.† Only

the materials and equipment involved in a boat you build will become its stated

value.

Highest and Best Use

Conventional wisdom says that building light is costly.†

If building light means carbon fiber, that is true.† If building light instead

means using superior engineering to configure the materials in efficient highest

and best use, it saves cost.

By now everybody knows

that rounded hull shapes give better performance, better water pressure resistance,

and more payload than slab sided, flat bottom boats.† Occasionally the thought

creeps up that if one builds just such a slab sided, hard chine, under performing

boat, you can save time and money.† For several reasons, that is not actually

true.† Look at it this way.† Suppose one has a 1000 kg of stack plywood or

cored sandwich to make into a pair of hulls.† The same stack of material will

give a longer, stronger and more easily driven rounded hull than the

dory bottom one will.† The rounded hull can have thinner skin for the

same strength due to the shape advantage. As Buckminster Fuller would have

said, one way gives more performances than the other.† That is highest and

best use of the materials.† That is one way to save money on building a boat.

Also, a traditional slab

sided dory hull requires that you build a strong-back first of all.† A rounded

efficient hull built with CM (Cylinder Mold, developed ply for big boats)

or another developed ply system does not need a strong-back to be built at

all.

Plywood vrs. Composite

Composite materials have

leapt up in price over the last few years.† I hear stories that it is the

military buying up all the carbon fiber, or the windmill manufacturers buying

all the epoxy and

foam, or some other reason.† Plywood

has gone up also, but not by nearly as much. †At my office the sales of plywood/epoxy

boats have surged recently.† A new 65í passenger ferry prototype is being

built near Seattle here using CM plywood.† It will be sent to Africa where

others like it will be built using local materials where possible.

A kilo of ply/epoxy boat structure costs some $9/kg. ($4/lb.)

compared to a kilo of foam/glass/epoxy structure costing some $13/kg. ($6/lb.)

You can now get even more boat for the dollar in plywood than in composite.†

That does involve several assumptions, but it is true.† Plywood often takes

a beating at the resale market, for no good reason, but it happens.† Epoxy

can successfully encapsulate and preserve a wood boat if it is designed for

it.† Properly repaired after crashes, the ply/epoxy boat will last as long

as a composite one.

Vacuum

bagging

table platen molding is recently popular as a composite

quicker build.† I say that a developed ply hull is still

faster to build than the heavily marketed bagging table

technique, and does not require building a bagging table.†

I strongly believe that a boatbuilder should be required

to build as few structures that will never see the water

as possible.† Developed plywood actually provides its

own ďbagging tableĒ.† Unlike with the heavily publicized

bagging table hull construction methods, plywood vacuum

bagged into cylinder-molded hulls becomes both the hull

and the bagging surface.† This is also true in a different

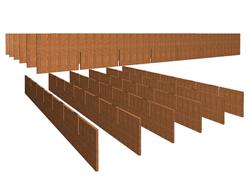

way for the deck and cabin structures.† A ply/core/ply

sandwich or a ply/core/glass sandwich can provide the

same results as a bagging table, without the time and

expense of building one. Its like this tilt-up

system, but with ply/core/ply.

Finally, a CM mold is easily broken down and can be sold

or traded to another builder. It can be carried in the

back of a compact pickup.† A full-length bagging table

is not easily broken down and shipped.

Plywood:

Plywood has gone up in price, but again,

not as quickly as the materials for composite boats.† Twenty years ago using

3mm thick doorskins to build good boats was viable.† Tested samples gave bending

strength of around 10,000 psi. Thatís not true now.† Still, I see good quality,

reasonably priced plywood for sale.† Plywood/epoxy boats will cost less than

composite boats and take less time to build.†

A fusion between

plywood and composite is often a cost saving.† I have long advocated a fusion

of plywood and composite materials where they are the best solution.†† Holo

Holo in Hawaii has foam/glass/epoxy hulls, but her bulkheads are ply/epoxy.†

She got the toughness advantages of foam/glass with the faster build time

and lower cost of plywood/epoxy beams and internals.† Her cabin is a ply/core/ply

sandwich that allows the house to be bagged to itself on the floor and assembled

like a tilt-up building.† That is also faster and cost saving.

Cheap plywood

is not a bargain.† Patching up cheap C grade plywood is not an actual cost

saving, even if it had the needed strength properties.† After the knot-holes

are wetted-out, filled and sanded, the cost will be as much as the grade of

plywood you should have bought in the first place, not to mention the time

spent.† Get that right at first.

However, inexpensive good

plywood may be available from China.† One link is http://www.greenlivable.net/.† They have

exterior plywood for under $4 per sheet there, but I do not know if they have

local vendors or what shipping costs are.

Resin:

For plywood boats, epoxy

resin is the only choice.† For composite boats, that could be true also.†

Epoxy is much more expensive than polyester or even vinylester.†

Vinylester is running about $3.40/lb at this time.† Epoxy is about double

that.† Still, the lower cost might be expensive in the long run.† Polyester

does not belong on any modern boat for several reasons.† I do know that a

few very famous designers have declared polyester just fine for your boat,

but the data does not support that.† Or you have to say what the meaning of

ďfineĒ is.† I will state that no boat worthy of the time you spend building

it should use polyester resin.

You

do often hear "my cat is polyester and it hasn't

cracked". That may be true, but note. It then either

has never been stressed, or it was designed with an

excessive safety factor. It is then far too heavy. Note

that a well designed fiberglass boat has critical parts

designed with safety factors of usually not more than

5 to 1.† Polyester resin has a stretch to failure of

about 1%.† E-glass has a stretch to failure of about

6%.† The result is a highly tension loaded part could

become a necklace of fiber with polyester chunks on

it.† More than that, in the marine environment, polyester

leeches out into the water as it bonds with the water

molecules.† It loses strength its entire life.† After

several years it will have about 20% the strength that

it started with. Also don't forget gel coat blisters.

With polyester, it is not if it will get blisters, but

when it will.

Vinylester has stretch to failure and other mechanical

properties similar to those of epoxy, at a lower cost.† I have had many successful

boats done with vinylester.† It is tougher to get right though for a backyard

builder.† The initiator and catylist proportions must be accurate to fractions

of a percent of volume, and must change during the day as a function of temperature

change.† With epoxy you can be, as I often say, brain dead.† If the temperature

is 15 C, itís a 5 to 1 or 2 to 1 ratio.† At 25 C, it is still 5 to 1 or 2

to 1.† Further, if the vinylester cure is not complete, it will never get

better.† With epoxy, the part can be post-cured later at any time and get

a complete cure.† None of this is visible, but it is real.†

Vinylester has a shorter

shelf-life than epoxy.† If your project gets interrupted, that can cost you

if you did a bulk-buy to save money.† In a recent issue of Multihulls Magazine,

Tom Pawlak notes

several other shortcomings of not

using epoxy resin, including excess shrinking of the part.

I understand that all the

epoxy resin sold here comes in the same tanker from China.† The various companies

come up with creative hardners to mix with the same resin.† I donít think

there is much chance to get a lower resin price.† I also place a premium on

vendorís experience in creating the hardners needed for the particular jobs.†

As a example of both, I just received some samples of a low cost epoxy. The

parts I coated looked ok.† However, when I tried to pop the wasted epoxy out

of the plastic cup the next day, the resin shattered like glass.† I would

not want to take a chance on my boat shattering the same way on an impact.†

The big boys may not have bargain epoxy, but they have the experience to create

resin toughness that is so important in the bumpy real world.† Negotiate with

them on price.

Resin Fillers

Epoxy fillers like WEST

407 make excellent fast fillet joints.† That is a phenolic (brown) microballoon

product with additives to help resist slumping.† Mixing your own filleting

blend with microspheres (white) will cost about 1/3 the price.† The

compression strength is about 60% that of microballoons.† It does have less

weight and absorbs less moisture than the balloons.

Wood powder

is strong and less expensive, but very heavy and hard to sand.

I am experimenting with

another product, perlite, by the brand name Dicaperl.† It looks and

feels like microspheres, but costing $20 for 34lbs, costs far less.† It does

not absorb moisture and sands easily.† I am using the highest grade, HP2000.†

I donít yet have any structural data on it being used as structural filler.†

This tip comes from Alex Mazurkewycz building one of my 45 cats.

Lumber:

Spar grade spruce is the best

material for structural lumber on your boat.† Other substutions have been

used in the past.† Fir is less expensive but heavier and tends to split

more easily.† It does however have better structural properties and could

result in slightly smaller stringers needed for example.† Wood like fir can

be ripped into thinner strips then laminated back together to make more robust

lumber.†

Many kinds of lumber have

been substituted for spruce by builders over the years.† By comparing modulus

of rupture or an E x I equation, your designer can vett a stringer substitution.

There is a website that has properties of hundreds of woods, maybe too

many, http://www2.fpl.fs.fed.us/TechSheets/techmenu.html

Foam/Glass Construction

Many construction situations

do require foam/glass construction.† Many good ways are possible to save construction

cost; still, some ways are false savings.

Infusion:

Infusion is the best way

to get a superior laminate product, this side of an autoclaved pre-preg.†

Once the system is worked out, high quality pieces can be turned out one after

the other.† Infusion does however take considerable setup time and testing

of the system.† On a production run, it is the only way to go.† On a one-off

boat, Iím not so sure.† Specialized core and or fabrics must be used.† If

the process fails in any way, the part probably has to be scrapped.

In my opinion, wetting

out and aggressively squeeging a laminate can give almost a good of a product,

with better control of where the resin is or is not.† It is more grunt work

during the wet out, but that goes fast.† Then, the part can be compacted with

vacuum bagging after the wet-out is done.

Resin:

Compared to ply/epoxy construction, the resin is an even

larger component of composite construction.† The same resin criterion as noted

before do apply.

Core Materials:

Core materials like CoreCell

http://www.atlcomposites.com/products/cores/end

grain balsa/index.htm (SEN) or Divinycell (crosslinked PVC)

http://www.diabgroup.com/europe/products/e_prods_2.html

are state of the art.† They are the rock stars of core and consequently are

shockingly expensive.† The last time I checked, a cubic foot (0.3 cubic meter)

of 100 kg foam core costs $65, bought in bulk.† Thatís about $5.50 per square

foot of 1Ē thick core.† Moreover, they might have long wait times to get.†

What about alternatives?

One tool I use to compare

core materials is a simple equation of shear strength in psi over weight

in lbs./cubic foot.† (Shear strength/weight=x)† I call it shear specific.†

For example 100 kg Divinycell gives a number of 36.† A heavier core with the

same strength will give a smaller number.† There are many other considerations,

but this is a good first start.† For example, honeycomb will give a higher

number, but has other problems.† Corecell will give a slightly lower number

as the shear number is lower, but it behaves differently and will perform

as well or better.† In testing lab results with Corecell samples, the laminate

always blew up before the core was significantly stressed.† That is a good

outcome.

What are the alternatives

to foam core?

Balsa core is less expensive than the foams

above, with slightly more weight and better shear strength.† It must however

be used with epoxy only and with best epoxy construction practice to keep

moisture out.† There may be problems with vessel value if built with balsa

core. If properly built, that should not be a problem, but that is a market

situation.† Balsa core is less expensive than the foams

above, with slightly more weight and better shear strength.† It must however

be used with epoxy only and with best epoxy construction practice to keep

moisture out.† There may be problems with vessel value if built with balsa

core. If properly built, that should not be a problem, but that is a market

situation.†

Balsa does not absorb impact

as well as the foams do.

Urethane foam costs much less than the rock star

foams.† There are many manufacturers, but one is General Plastics http://www.generalplastics.com/products/index.php?PHPSESSID=6ac3fdb313fb070a2d6a8f4d0f5eb4a4.

Several times a year I get asked if urethane foam is a good substitute for

PVC or SEN.† It is not.† To get adequate shear strength, Scott Lewett at Structural

Composites tells me that the urethane core needs to have about double the

density of the PVC or SEN to do the same job.† Whatís more, it crumbles much

more easily under repeat load.† It is called being friable.† Your boat could

see a lot of repeat load.† Friable core is thus not acceptable. Urethane foam costs much less than the rock star

foams.† There are many manufacturers, but one is General Plastics http://www.generalplastics.com/products/index.php?PHPSESSID=6ac3fdb313fb070a2d6a8f4d0f5eb4a4.

Several times a year I get asked if urethane foam is a good substitute for

PVC or SEN.† It is not.† To get adequate shear strength, Scott Lewett at Structural

Composites tells me that the urethane core needs to have about double the

density of the PVC or SEN to do the same job.† Whatís more, it crumbles much

more easily under repeat load.† It is called being friable.† Your boat could

see a lot of repeat load.† Friable core is thus not acceptable.

Coretex, a fiber reinforced urethane foam is still weak, but it has relatively

high weight.† I see no use for it in multihulls or light monohulls.

Nida Core http://www.nida-core.com/† has evolved in the last few years.†

Look into the latest offerings.† The original Nida-Core is a polypropylene

honeycomb used as a core in sandwich panels.† It comes covered with a non-woven

polyester scrimm that is thermofused to the cells.† This covering helps bonding

properties and keeps resin out of the cells.† The density is 4.8 pounds per

cubic foot.† The shear strength ranges from 70 psi to 130 psi.† That gives

a shear specific of 14.6 to 27.† It is available with foam filling.† I see

it as being most useful for interior furnishings, but the weight is a bit

high for that.† Corners cannot be easily faired into a radius.† Nidacore has

superior sound deadening properties to foams or balsa of similar densities.†

Again, lately they have greatly expanded their product line. Nida Core http://www.nida-core.com/† has evolved in the last few years.†

Look into the latest offerings.† The original Nida-Core is a polypropylene

honeycomb used as a core in sandwich panels.† It comes covered with a non-woven

polyester scrimm that is thermofused to the cells.† This covering helps bonding

properties and keeps resin out of the cells.† The density is 4.8 pounds per

cubic foot.† The shear strength ranges from 70 psi to 130 psi.† That gives

a shear specific of 14.6 to 27.† It is available with foam filling.† I see

it as being most useful for interior furnishings, but the weight is a bit

high for that.† Corners cannot be easily faired into a radius.† Nidacore has

superior sound deadening properties to foams or balsa of similar densities.†

Again, lately they have greatly expanded their product line.

Polycore http://www.polycore.com.au/ looks similar

to Nida, but claims better mechanical properties.† Density is 80 kg (4.8 lb/cf)

and core shear strength is 0.8 MPA or 109 psi.† It gives shear specific number

of 21.8.

Plascore http://www.plascore.com/index.htm

has a variety of honeycomb core materials.† The most useful one to boatbuilders

has polypropylene core and seems to be like Nidacore

or Polycore.

Styrofoam has core shear strength that is so

low it is measured in psf. (pounds per square foot) not psi as the usual foams

are.† Enough said.

Norcore (Raven Industries) and†† http://www.pepcore.com/products.html#

A plastic honeycomb

made from a variety of plastics including PEI, PC, ABS, HIPS, and SURLYN.†

Available in thickness from .5 inch to 3 inches.† Strength unfortunately goes

down with increased thickness.† One inch thick Norcore has a weight of 10#

per cubic foot but a compressive strength of only 224 psi.††† It is a very

rigid "live core" and cannot be bent.† Corners cannot be easily

faired into a radius. In a 1Ē thickness the polystyrene core weighs 9.7 lb/cf.

and has shear strength of 105 psi.† In polycarbonate the core weighs 13.3

lb/cf and gives shear strength of 142 psi.† In polyprophelene the core weighs

10.68 lb/cf and gives 57 psi.† The best shear specific number is 10.67. A plastic honeycomb

made from a variety of plastics including PEI, PC, ABS, HIPS, and SURLYN.†

Available in thickness from .5 inch to 3 inches.† Strength unfortunately goes

down with increased thickness.† One inch thick Norcore has a weight of 10#

per cubic foot but a compressive strength of only 224 psi.††† It is a very

rigid "live core" and cannot be bent.† Corners cannot be easily

faired into a radius. In a 1Ē thickness the polystyrene core weighs 9.7 lb/cf.

and has shear strength of 105 psi.† In polycarbonate the core weighs 13.3

lb/cf and gives shear strength of 142 psi.† In polyprophelene the core weighs

10.68 lb/cf and gives 57 psi.† The best shear specific number is 10.67.

Nomex††††††††††††† A hexagonal honeycomb made from DuPont aramid paper sheets.†

A thermosetting resin is used to bond these sheets at the nodes.† After expanding,

the block of paper is dipped in a phenolic resin.† A variety of cell sizes,

core and paper thicknesses, and densities can be produced.† Flat panels can

use the hexagonal cell, but doubly curved surfaces such as the side of a hull

must use an over-expanded cell to conform to the curves.† While the paper

appears to be very waterproof, work I have seen by the Boeing company suggests

that water will condense in the cells over time.† I do not recommend honeycomb

for the primary structural parts of a multihull.† I do use honeycomb for bunk

boards, soles, shelves and cabinetry.† Corners cannot be easily faired into

a radius.† Some tricks are required to vacuum bag glass onto bare honeycomb.

One nice product that uses honeycomb is Tricel.† It

is used for interior surfaces.† It consists of thin plywood faces bonded to

a honeycomb core.† Weight is very good.† See http://www.tricelcorp.com/.

Core Craft FRP Honeycomb†††††††† http://www.infracomp.com/index.html

Custom fiber reinforced plastic honeycomb panels of 1"

thickness to 30" thickness.† Panels may be flat or slightly curved and

up to 12' wide with unlimited length.† Compression strength of core can range

between 100 psi and 1000 psi.† May be good for large charter boat bridgedecks.†

I don't know what price is like.

Penske††††††††††††† Marketed as a replacement for plywood.† A glass reinforced

urethane.† Now owned by Alcan, it is called PXC.† It seems to be too heavy

for multihulls and light monos.† Cost is about like pvc foam.

One client is using Paulowina

wood for core in place of balsa as it costs much less.† It is heavier

than balsa at 15 to 19 pounds per cubic foot ( balsa averages 11 lbs/cuft),

but has better structural properties.† The bending modulus is double that

of balsa.† I donít find a shear strength printed, but Iím confident it is

much better than balsa.† It would need to be hot coated with a tie-coat like

bare balsa must be.† I have no personal experience with it yet, but it looks

very interesting. †See http://www.paulowniawood.com/as

a starting place.

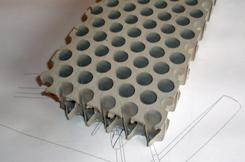

I must admit I had forgotten about

eggcrate plywood.† We used to use that back in the 70s when foam was

not really available.† That is where a grid of thin plywood bits are interlocked

together to form a kind of cellular core.† Testing is being done to determine

the best frequency and depth.† It is much more work, but far less cost than

core.† Also, new considerations pop up.† All the spaces must be vented, but

pests could then enter.† If the boat is traveling, customs tends to be very

interested in voids that they cannot see into.† That could be harsh. I must admit I had forgotten about

eggcrate plywood.† We used to use that back in the 70s when foam was

not really available.† That is where a grid of thin plywood bits are interlocked

together to form a kind of cellular core.† Testing is being done to determine

the best frequency and depth.† It is much more work, but far less cost than

core.† Also, new considerations pop up.† All the spaces must be vented, but

pests could then enter.† If the boat is traveling, customs tends to be very

interested in voids that they cannot see into.† That could be harsh.

This is not intended to

be an exhaustive list of cores.† It is simply a few of the possible choices.†

Iím sure there are many more.† I could not make it to the last IBEX so there

may be new cores that I do not yet know about.

Composite w/Stringers

Many, but not all composite

parts can be redesigned to use solid laminate and composite stringers.† That

substitution design must be done by your designer.

Fabrics:

Many long, slender parts

like masts, beams or boards are really best done with carbon fiber.† Have

I mentioned that it is expensive?†

One work-around that can

actually give even better results is a hybrid part.† All the longitudinal,

deflection-driven fibers must be carbon.† The off-axis fibers however are

not nearly as highly loaded, depending on the part.† They often can be glass.†

As an added benefit, they give the carbon part some extra resilience while

not sacrificing overall stiffness.† Again, consult your designer to see if

part involved can benefit from that substitution.

Be careful about yard-sale

fiberglass deals.† Water damaged fabrics must be avoided.† If the binder

or sizing is washed away, it might not bond properly to the resin.

I have heard about great

prices for fabrics from China recently.† Do test a sample or have assurance

that the binder or sizing coating on the fabric is compatible with epoxy.

Peel

Ply:

I have heard designers

say that dressmakers nylon can be used as peel ply to save money.† No.† That

is a bad substitution.† Peel ply must be free of contaminants.† If your resin

seller supplies it for example, it will surely be free of those contaminants,

unlike the dressmakerís nylon.

Scraps of 4 oz. or 6 oz.

cloth make the best peel ply on compound shapes or odd corners.† Save those

scraps.

Vacuum bagging and Infusion

Equipment:

An excellent vacuum bagging kit can

be purchased from various suppliers costing from $300

to three times that.† They have excellent pumps, nylon

bagging film, and dum-dum edge sealer.† These low volume,

high vacuum pressure pumps are excellent for composite

laminates, especially with infusion techniques.† They

start at over $300 for the pump alone typically.†

You probably have a compressor already.†

In that case, get a venturi vacuum pump that plugs into

your compressor for just over $100.

If you are not planning to use infusion, there is an even

lower cost option.† A standard shop vacuum will pull one third of an atmosphere

(4 to 5 psi) and cost, well, you probably have one already.† Bagging film

can be inexpensive polyethelene film, 4mil (0.004Ē) or 6mil (0.006Ē) thick.††

Compare the low cost of poly. film† to nylon bagging film costing $3/yd.†

The bag edges can be sealed

with inexpensive storm window sealer (Frost King by Thermwell Products http://beatlas.com)

instead of the expensive but vulnerable high-end edge sealer products.† The

joints or corners take a shot of plywood panel adhesive (Liquid Nails).

Designer Involvement:

Involving the designer

can often save a lot of materials and work.† Running a finite element study

on a change or a substitution can possibly save more than its cost in materials.

Even a simple section property simulation on a change can cost very little

from the designer, and save a lot of materials.

Typically multihulls builders donít like to pay designers

to do that sort of work, but it can save more than it costs.

Paint:

Two part polyurethane paints

like Awlgrip or Stirling will resist stains and look great for years.† I have

walked out of the paint store carrying a box that has a thousand dollars worth

of paint in it.† Are there any less costly substitutes to those top of the

line paints?

First, you must keep the

gloss.† Itís not a vanity, it keeps stains from building up.††† In my experience

one part paints will not keep gloss for more than a summer.

To save money, find an

industrial paint supplier in your area and see what they have.† I learned

about Jarvie (Now Farwest www.farwestpaint.com)† paint here in Seattle when I worked

for a boatyard while I was in architecture school.† For example, they sell

a primer that is a fraction of the price of Awlgrip 545, yet seems to be virtually

the same product.

Buildings:

Donít build outdoors.†

If you donít have a shop already, there are several options.

I have built a boat at

a storage complex.† The cost is quite reasonable.† Usually it must

be built in components and assembled later as noted below.† Similarly, one

of my builders has boatbuilding spaces available.† http://www.theshoppeople.com/.† He is

in Portland, OR, but the same kinds of spaces could be in your area.

Inflatable pool covers

can be bought new for typically less than 6 months rent in a shop space.†

The market is full of portable

temporary buildings that can work very well.

Clubs, Craigslist, Ebay

Multihull clubs are in

the wane, apparently. They used to give builders the price advantages of bulk

buying. Maybe the fact that many of us have our own business licenses now

and can get just as good prices contributed has contributed to the decline

of clubs.

If your boat is built as a

business, your tax number will get significant discounts.

Ebay and Craigslist are

great places to buy things for your boat.† Donít expect

to find basic materials as often, but you can find masts,

sails, hardware and the unexpected.†

For price comparisons on

boatbuilding products there are many distributors.† Among them Jamestown Dist.

http://www.jamestowndistributors.com/userportal/main.do,

and Fiberlay http://www.fiberlay.com/.

Building Components First

Many multihulls can be

built in smaller components, in a smaller shop space than will be needed later

on for a final, full size vessel.† The designer may need to do some plans

revisions to facilitate that remote assembly.† That will save shop rent.

Miscellaneous Tips

Save paper cups

from fast food or Starbucks trips.† These are especially

good for mixing small batches of bog.

Buy the black foam rollers

(Jen Manufacturing), not the yellow ones.† They cost a fraction of the cost

of the yellow ones.† Buy them by the box.† Cut them in half for smaller jobs

using the half roller.† Cut into smaller bits they can be used as foam brush

substitutes.

Mold release wax

rubbed onto plastic mixing buckets or squeeges helps keep epoxy from sticking

to them for the next use.† That will make them last longer.

Very

small epoxy batches can be measured by dribbling

epoxy and hardner into a pair of properly sized adjacent

circles printed on a piece of paper.† Mix the two. This

trick is from J.R. Watson, presented at IBEX.

In an emergency, plastic

sandwich bags can be used as gloves.†

When vacuum-bagging with

plywood, regular mailing bubble pak can be used

as a diffuser inside† the bag.

Material

waste is typically 20%. Think about how you can reduce

that.

Always

have another part ready for coating or bogging if too

much resin or bog was mixed for the main part.

Conclusion

Despite bleak economic

news, with some of the above tips, a reasonably priced boat can be built.†

In fact, there may be no better time to negotiate the best prices on boat-building

materials, services, and dare I say, even plans than now.

|